Enabling technologies

Six key highly innovative enabling technologies will be further developed and implemented alongside the demonstrators, elevating the innovation of USES4HEAT to even greater heights.

USES4HEAT Innovation

Advanced drilling equipment and machines for aquifer thermal energy storage (ATES)

Innovative piping for high temperature borehole thermal energy storage (BTES)

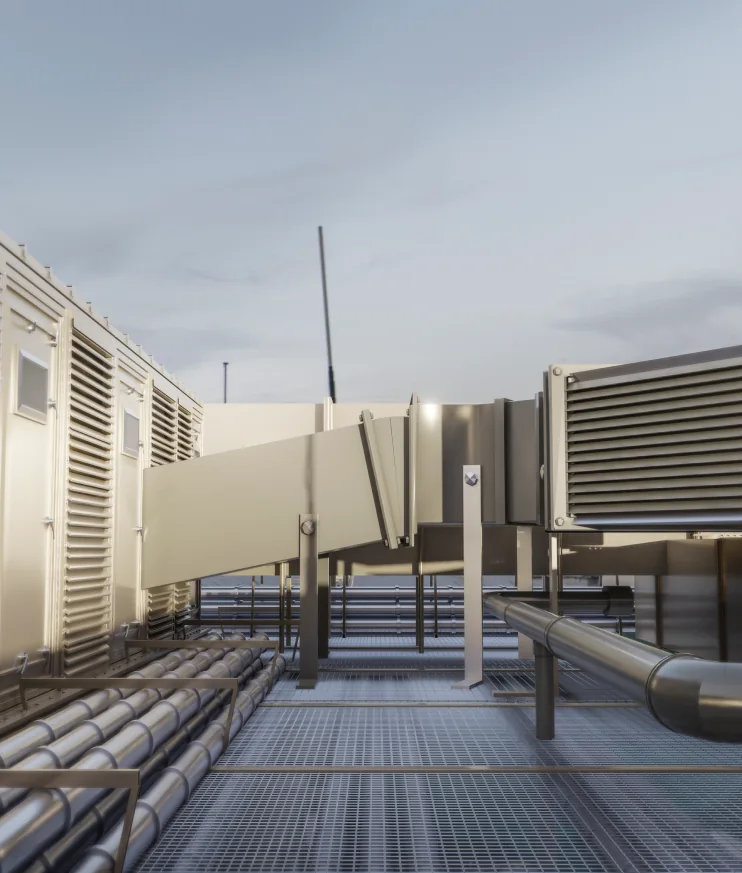

Groundwater high temperature heat pump (HP) integrated with ATES and DH

Efficient photovoltaic thermal (PVT) integrated with ATES

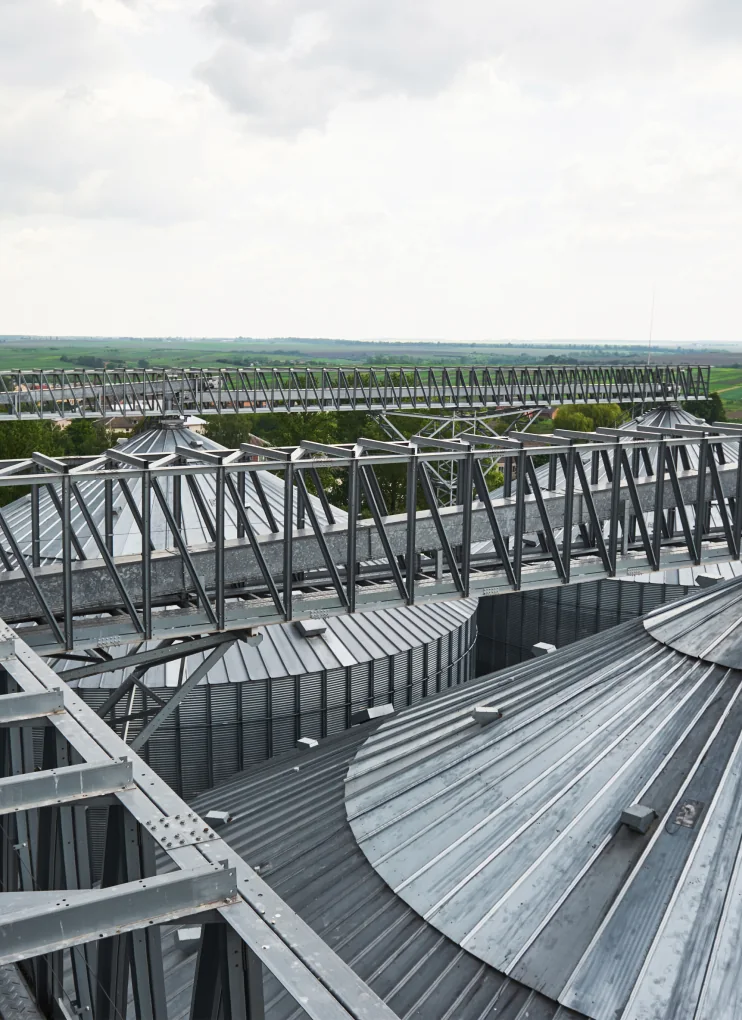

Integrated solar thermal collectors (STC) for BTES charging and district heating connection

Intelligent Energy Management Hub

Demonstration sites

and replicators

Reduce drilling construction time and cost, improve safety of workers conditions, maximise flexibility of drilling machines to adapt to different ground conditions

Ensure pipes extended lifetime at high temperature and pressure once installed in BTES and reduce associated maintenance and costs

Commercial heat sink temperature for ground water HP of about 75-80°C, with low Coefficient of Performance (COP) and high Global Warming Potential (GWP) and lack of experience in industrial scale HP operation for sector coupling and power grid flexibility

Limited conversion efficiencies of commercial PVT units, elevated costs which limit their adoption with respect to PV and no experience with PVT integration in ATES based heating systems and for ATES charge

Limited capacity factors attainable without TES integration, elevated costs which limit their adoption and lack of experience with STC integration for BTES charging (at temperature higher than 50°C)

Lack of data and operational experience at large scale to set up AI based tools for intelligent energy management ensuring maximisation of energy buffering of seasonal TES

Progress beyond the state of the art

Innovative drilling head Easy-Drill capable of drill even the most difficult terrains, new remotely controlled drilling machine

Layered plastic based pipes, with improved safety factors, durability and mechanical resistance

Cutting-edge HP technology with high COP, low GWP, and capability to achieve 90°C on the condenser side, ideal for seamless integration into high temperature district heating networks while offering grid flexibility and participation in the electricity market

Innovative PVT units featuring enhanced PV laminate and advanced absorber material for optimal conversion efficiency, facilitating comprehensive system integration to maximize sector coupling benefits

Highly efficient and cost-effective STC integrated in high temperature BTES (maximum temperature of 95°C) for capacity factor maximisation

Capitalisation of previous project datasets, data from experimental campaigns at two demo sites, and dynamic models to develop tailored AI, big data analytics and cloud-based energy management tool